More efficient, safer, more compatible: the innovative ROLLTAINER® with plug-in system sets new standards

Optimizing storage areas and logistics processes is a constant challenge. The handling and compaction of empties in particular can take up valuable time and space. We are pleased to introduce a ground-breaking solution: the new ROLLTAINER® with innovative plug-in system that will revolutionize your storage and transport logistics. This mesh trolley combines high-quality construction with a clever design for maximum efficiency and safety.

Intelligent design for maximum space utilization

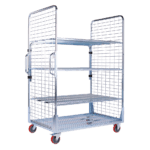

The heart of the new ROLLTAINER® is its plastic roll top made of high-quality HDPE material, equipped with an innovative plug-in system. This makes it possible to insert four side rails firmly and securely in the middle. There is space for four more side rails in between. But that’s not all: four additional plastic roller panels can be fitted to the left and right of the inserted side rails. This sophisticated system allows empties to be compacted quickly and systematically like never before. In comparison to classic empties compaction, each storage space can be utilized up to 150% better – an enormous advantage for your storage capacity. Alternatively, only side racks can be stored to save space.

High occupational safety and sustainable integration

In addition to outstanding efficiency, the focus during development was on occupational safety. The fixed slots for the four main side rails prevent them from slipping or falling out, thus ensuring safe transportation and handling.

Another plus point is sustainability and cost-effectiveness: the new roller plate is 100% compatible with existing components. You do not need to purchase new side rails. Side rails with a lockable step bar work perfectly. This is not only easy on your budget, but also promotes sustainable storage and resource-saving transportation of empties.

Quality and adaptability in detail

The ROLLTAINER® impresses with its robust construction. The side rails are made of Ø 22 mm round tube with a 12 x 3 mm flat iron infill and a stabilizing central cross tube (Ø 16 mm). The galvanized blue surface ensures durability and corrosion protection. The roll container is fitted as standard with smooth-running Ø 108 mm polypropylene castors (two swivel and two fixed castors). Three different usable heights are available for specific requirements.

Optionally, the rolltainers can be fitted with swivel castors with central brakes and/or central directional locks on both sides to further increase maneuverability and safety.

Optimize your logistics now!

The new ROLLTAINER® with plug-in system is the ideal solution for companies that want to make optimum use of their storage space, increase efficiency when compacting empties and improve occupational safety. Benefit from maximum compatibility and a sustainable approach.

Would you like to find out more or receive detailed advice on your specific requirements? Feel free to contact us! Our team of experts is at your disposal.